Vacuum Systems with Pump

The operation of liquid ring vacuum pumps can be carried out in three ways:

-

Without any recirculation (see Vacuum Pumps Section)

-

Partial recirculation

-

Total recovery

Partial Recirculation

In the case of partial recirculation, the sealing liquid enters and leaves the pump as no recirculation case. After that, part of the sealing liquid from the separator tank is recirculated to the pump and the remaining is drained. On the other hand, fresh sealing liquid is added to the system, as much as necessary to maintain the proper temperature, which is essential for the correct performance of the pump. This type of arrangement is used when sealing liquid conservation is important (the consumption of fresh water can be reduced up to 50%, and if another liquid is used, the consumption can be reduced more than 50% depending on the vapour pressure and fluid temperature).

Total Recovery

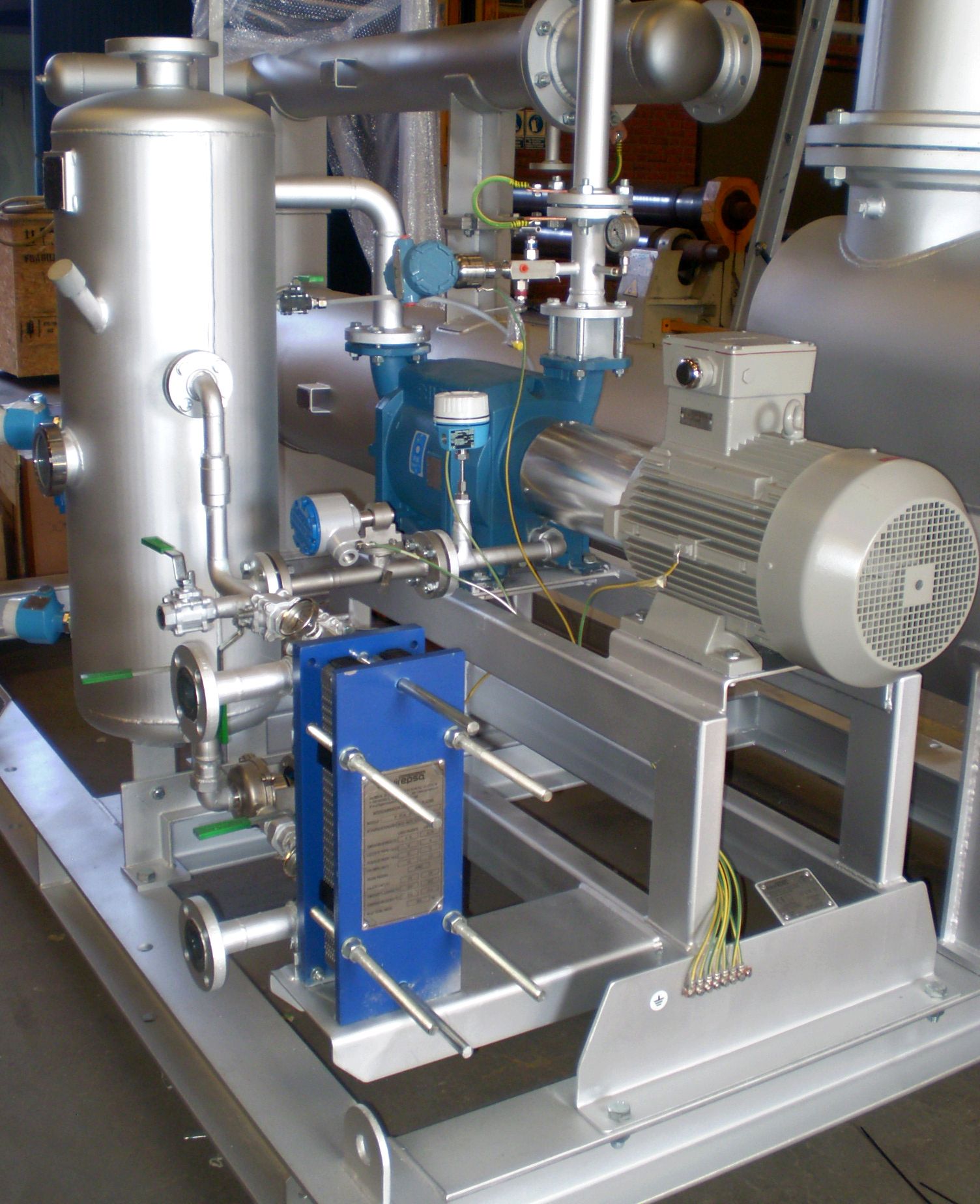

In the case of total recovery, there is a total recirculation of the sealing fluid. In this case, a heat exchanger (plates or shell and tubes) is added to the system in order to dissipate the heat of compression and condensation from the sealing liquid before being reintroduced into the pump. For long periods of operation and high suction pressure values, and when the system (exchanger, piping, valves, …) has an excessive pressure drop, it may be required a recirculation pump.

Additionally, there are other possibilities of vacuum systems with pump:

-

Total recirculation systems with air ejector: An air ejector is used before the pump to reach suction pressure values lower than 33 mbar a, about 10 mbar a depending on service liquid temperature.

-

Oil total recirculation systems: The liquid ring fluid is oil, which is cooled before entering into the pump, with a heat exchanger.

EQUIREPSA supplies vacuum systems with pump completely custom and according to the specifications and needs of each client (loose equipment, complete skids with valves and instrumentation, etc…).